Case Study: Refitting a news studio to efficient LEDs at NBC Cleveland

Subscribe to NCS for the latest news, project case studies and product announcements in broadcast technology, creative design and engineering delivered to your inbox.

LED lighting technology has re-shaped our society in recent years. From screens of all sizes to the lights in the parking lot, to the animated accent lighting in buildings around the world, the light-emitting diode has replaced all other methods of creating light. Its versatility, efficiency and longevity have made it a staple of the 21st century.

LEDs create little heat, consume much less electricity and have a significantly greater useable life. Power is a major expense in a television studio both in operating the lights as well as removing the heat they create. It is not unusual to see wattage consumed at a TV news studio in the upper five figures.

Conventional lighting fixtures require bulb changes and other maintenance on a yearly basis. Professional LED fixtures are good for a minimum of 50,000 hours of operation. That’s approximately 10 years of heavy studio operation.

What does it take to convert a conventionally lit studio to LED based lighting? An example is a recent project done at the Tegna-owned NBC affiliate, WKYC in Cleveland.

Vincent Lighting Systems was contracted to provide a turnkey solution for WKYC’s main news studio.

This included removal of the existing legacy lighting, supply and installation of new LED lighting fixtures, design and commissioning of a custom control system, and installation labor coordination. I was brought in as Lighting Director to design and specify the lighting system and set the on-screen look.

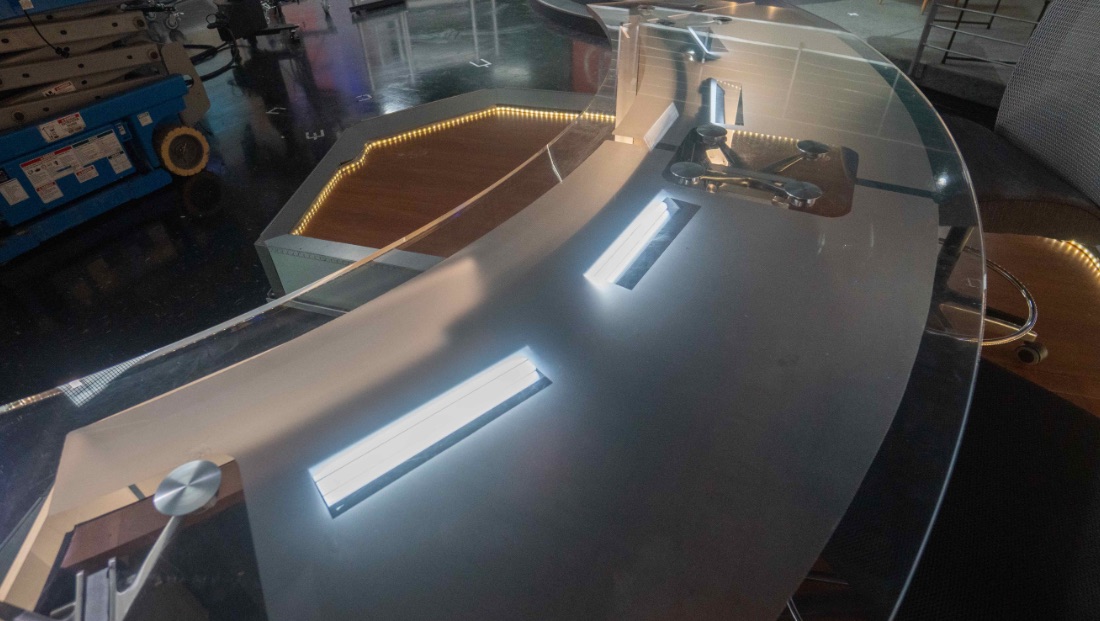

Lighting at the studio of WKYC. Photos courtesy of Nicholas Hutak.

As LED fixtures have developed over the last several years, certain fixture types and brands have risen to the top. Although they last far longer than traditional light sources, most LEDs degrade over time as the phosphor that creates the color is mounted directly onto the LED itself. Remote Phosphor fixtures hedge against this wasting by separating the phosphor that creates the color, from the LED. This extends the color consistency of the unit well over the 50,000-hour LED runtime average.

Although LED fixtures create little heat they are heat sensitive—so cooling is critical. This can be done using fans or with passive cooling performed without moving parts. My choice in a high-usage situation is passive cooled remote phosphor fixtures.

For this project, I selected BB&S Lighting fixtures as the primary light source. Their remote phosphor Pipeline Reflect three-foot and four-foot, four-bank fixtures provide base and fill light. The Area 48, a smaller, remote phosphor fixture provides a “soft key” light for each position. What I like most about these remote phosphor panel fixtures is the way they render flesh tones. They also have more punch, that is, more apparent illuminating power than traditional LEDs of the same wattage.

The 1’ Pipeline Reflect fits perfectly into the desk providing the all-important and flattering facial up-light. The size and mounting options of this small and very efficient fixture made installation by the VLS team possible in an existing desktop. A new item in the BB&S line-up, the Compact Beam Light made for a great long throw backlight from 25-feet away.

Chroma Key and video wall areas are always challenging. I was able to use BB&S Pipeline 6’ single bank units just over the screens and out of camera shot to provide backlight on presenters 3-feet from the wall. The same long narrow fixtures work extremely well in the Chroma Key area.

As with many established studios, WKYC had several ETC Source-4 ellipsoidal fixtures in their existing inventory. I was able to replace the “light engine” in these formerly tungsten units with their LED retrofit, the Source 4WRD, a savings over a completely new fixture.

Additionally, there’s the DeSisti Picoletto. This very small and versatile fresnel spotlight made for great backlight in the tight spaces around the edges of the studio. All fixtures were 5600°K. I find that monitors and video walls are more easily balanced to this color temperature.

Using daylight balance was also suggested as the studio has a view to the outdoors in some areas. Unlike conventional fixtures that require filters to create color, color-changing LED fixtures can create millions of colors with instant precision control. Several were used to freshen up some of the set lighting.

All of this technology must be controlled. Once it is up and running, each presenter is brought into their position and custom lighting for that individual is set and placed in memory. The VLS CoPilot Broadcast system can then recall that setting either through studio automation or by dragging a presenter’s picture into the position they sit in on a map of the studio. This is an invaluable feature in the world of shrinking studio staff. This entire package was designed for future expansion as the lighting control system itself has the ability to control far more than what is currently in use and can be programmed and maintained remotely by VLS technicians as studio needs develop.

The entire installation took 5 days. One was for demolition and infrastructure preparation. It took three to hang, focus and do basic programming. The final day was for the walk-through and fine-tuning. The work began several months in advance with a site visit and meetings with the lead director and the close support of the VLS team in Cleveland. Prior to the LED refit, the studio consumed 40,000 Watts. It now consumes 7000 Watts.

This new ultra-efficient studio consumes considerably less power, eliminates the man-hours for lamp changes, and will maintain the lighting’s stable color characteristics for the next decade.

Nicholas Hutak is a two-time Emmy Award-winning lighting designer with 132 broadcast news studios on 4 continents to his credit. He can be reached at nh@nickhutakdp.com or online here.

Subscribe to NCS for the latest news, project case studies and product announcements in broadcast technology, creative design and engineering delivered to your inbox.

tags

BB&S Lighting, desisti, desisti lighting, lighting design, Nicholas Hutak, Tegna, tv lighting design, Vincent Lighting Systems, wkyc

categories

Broadcast Lighting Design, Case Study, Featured, Lighting and Lighting Design, Voices